-

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Expanded PTFE (Teflon®) gasket material is produced by expanding Virgin PTFE using a process that creates a uniform and highly fibrillated microstructure with equal tensile strength in all directions.

The EPTFE variant of the gaskets have high creep resistance and can be used with medicine as well as food processing industries. They are non-corrosive, has best insulation available and is fully odorless for smooth operating.

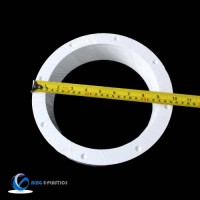

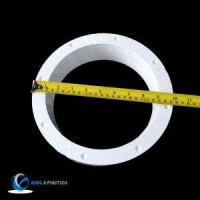

Expanded PTFE is great to be used as a sealing material in bolted flange joints in pipelines, hydraulic systems, and pneumatic systems. Expanded PTFE is typically known to be an affordable alternative to sheet gaskets on flanges with large diameters where cutting the sheet is unrealistic. The flexibility of this unique material allows it to fit any flange shape, therefore it is unnecessary to stock a variety of gasket shapes and sizes.

| NO. | ITEM | UNIT | TEST RESULTS | REMARK |

| 1 | Density | g/cm3 | 0.86 | GB/T22308 |

| 2 | Maximum Service Temperature | ℃ | 260℃ | GB/T22308 |

| 3 | Minimum Service Temperature | ℃ | (-210℃) | GB/T22308 |

| 4 | Maxium Pressure | 1200Psig | 83 barg | GB/T22308 |

| 5 | Compressibility | % | 59.55 | ASTM F36,GB/T20671.2 PRESSURE 35MPA |

| 6 | Resilience Ratio | % | 11.61 | |

| 7 | Creep relaxation rate | % | 68.32 | ASTM F38,GB/T20671.5 100℃*22hr |

| 9 | Compressibility rate | % | 51.26 | JB/T10688 Pressure 17.25Mpa |

| 10 | Resilience Ratio | % | 14.35 | |

| 11 | Nitrogen leakage rate | m1/sec | 0.16 | JB/T10688 Pressure 17.25Mpa Internal Pressure of Medium(N2):4Mpa |

| 12 | Nitrogen leakage rate | m1/sec | 0.0037 | Pressure :35Mpa Internal pressure of Medium(N2):4Mpa |

| remarks:+ and 0 mean depending on situation.- is not. | ||||