-

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

MOQ:

Default

MOQ:

Default

Port:

Hangzhou

Port:

Hangzhou

Packaging:

Customizable

Packaging:

Customizable

Lead Time:

Default

Lead Time:

Default

Size:

Default Size

Size:

Default Size

Color:

Default Color

Color:

Default Color

Place of Origin: Guangzhou, China (Mainland)

Brand Name: Ninge

Model Number: plastic sheet

Material: heat resistant plastic sheet

Thickness: Customized

Size: Custom Size

Item: for heat resistant plastic sheet

free sample: available

Color: Black /white /red

Certificate: ISO9001

Feature: Eco-Friendly

Density: 1.5g/cm3

shape: Sheet

warranty: yes

Package: wooden box

Tensile Strength: Strong

POMC sheet :thickness :8-120M

Size:600*1200/1000*2000mm

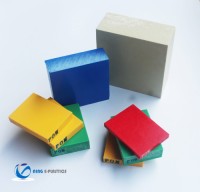

Acetal Delrin Sheet

Acetal resins (polyoxymethylene or POM) are engineering thermoplastics based on formaldehyde polymerization technology. Acetal resins have high tensile strength, stiffness, resilience, fatigue endurance, a low coefficient of friction against metals, acetals and other plastics and moderate toughness. The Acetal sheet has high resistance to organic solvents, excellent dimensional stability, a low coefficient of friction and outstanding abrasion resistance among thermoplastics.

Acetals’ resistance to creep is excellent. Moisture, lubricants and solvents including gasoline and gasohol have little effect on this property, which is important in parts incorporating self-threading screws or interference fits. Good electrical properties qualify these materials for electrical applications requiring long-term stability. Acetal copolymers retain much of their toughness through a broad temperature range and are among the most creepresistant of the crystalline thermoplastics. A low moisture absorption characteristic permits molded parts to serve reliably in environments involving humidity variations.

POM sheet or poly oxy methylene (POM) is a name of popular plastics which are widely used in the engineering world. POM sheets are also known as acetal, polyacetal, and polyformaldehyde.

POM sheets and plates are counted among stiffest of all thermoplastics. They’re generally produced by different chemical firms with slightly different formulas such as; Ramtal, Delrin, Celcon, Duracon, Kepital, and Host form.

The POM sheets are divided into two types;

It has high chemical resistance, it regularly brings about less warm debasement while generation, and in the field.

The best features pf POM sheets are given below;

The few highlighting properties of POM sheets are;

| PROPERTIES | STANDARD | UNIT | RESULT |

| mechanical property | |||

| Density | ASTM D792 | g/cm3 | 1.43 |

| Tensile strength | ASTM D638 | Mpa | 100 |

| ultimate elongation | ASTM D638 | % | 10 |

| bending strength | ASTM 790 | Mpa | 150 |

| bending modulus | ASTM 790 | Mpa | 4500 |

| hardness | ASTM D2240 | D | 85 |

| Impact strength | ASTM D256 | J/M | 100 |

| Thermal properties | |||

| Melting poing | DSC | ℃ | 190 |

| working Temp. | ASTM D648 | ℃ | 140 |

| Permanent Temp. | – | ℃ | 120 |

| Short-period Temp. | – | ℃ | 150 |

| Pyroconductivity | DIN 52612-1 | W/(K-M) | 0.31 |

| dilatation coefficient | ASTM D696 | 10-5-1/K | 6 |

| electrical property | |||

| dielectric strength | ASTM D150 | KV-mm | 22 |

| dielectric loss coefficient | ASTM D150 | – | 0.005 |

| Volume resistance | ASTM D257 | Ω.cm | 1014 |

| surface resistance | ASTM D257 | Ω | 1016 |

| dielectric constant | ASTM D149 | – | 3.9 |

| Chemical properties | |||

| Water absorption | 23℃ 60%RH | % | 0.35 |

| Acid resistance | 23℃ 60%RH | + | |

| Alkali resistance | + | ||

| Resistance to acid and alkali water | + | ||

| Chloric acid alkali resistance | 0 | ||

| Resistant to aromatic compounds | + | ||

| The ketone resistance | 23℃ 60%RH | + | |

| Water resistance | 23℃ 60%RH | + | |

| Others properties | |||

| combustibility | UL 94 | HB | |

| paste | – | + | |

| Non-toxic harmless | EEC 90/128 FDA | + | |

| friction coefficient | DIN 53375 | – | |

| uvioresistant | – | 0 | |