-

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Place of Origin: Guangzhou, China (Mainland)

Brand Name: Ninge

Model Number MC-Nylon Board

Material: PA6, PA6

Thickness: 5mm-300mm, 5mm-300mm

Size: 2.1*1.1m/2.5m*1.2m/3.2m*1.3m, 2.1*1.1m/2.5m*1.2m/3.2m*1.3m or Customized

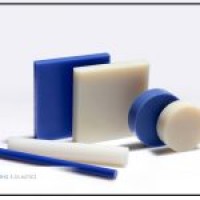

Product name: mc nylon sheet price

Density: 1.15g/cm3

Color: White/Black/ Gree/Blue/Red/natural colour /yellow

Certificate: SGS

Shape: Square

Parking: Wooden Carton

Application: Chemical machinery, anti-corrosion equipment gear,ect

PA 6 sheet thickness :8-200mm

Size:1000*2000,1200*2400mm

Nylon Sheet

Nylon was the first engineering resin and has been used in applications ranging from electronic, marine, and automotive industries to fibers used to make carpet. Nylon sheet has outstanding wear resistance and low frictional properties.

Nylon has very good temperature, chemical, and impact properties. Parts machined or fabricated from nylon are light weight and corrosion resistant. Low friction, good abrasion resistance and the ability to operate without lubrication, qualify the nylons for such applications. Parts machined or fabricated from cast nylon are light weight and corrosion resistant. In addition, cast nylon’s excellent load bearing capability, wear resistance and impact resistance make it ideal for demanding construction environments.

Nylon sheet which has not been compounded with UV stabilizers are sensitive to ultraviolet light. These compounds should not be used for extended outdoor service. Carbonblack (our black Nylon Sheet) is the most effective of the UV stabilizers. These additives also increase tensile strength and hardness and decrease ductility and toughness slightly.

| PROPERTIES | STANDARD | UNIT | RESULT |

| mechanical property | |||

| Density | ASTM D792 | g/cm3 | 1.13 |

| Tensile strength | ASTM D638 | Mpa | 74 |

| ultimate elongation | ASTM D638 | % | 5 |

| bending strength | ASTM 790 | Mpa | 90 |

| bending modulus | ASTM 790 | Mpa | 2200 |

| hardness | ASTM D2240 | D | 85 |

| Impact strength | ASTM D256 | J/M | 50 |

| Thermal properties | |||

| Melting poing | DSC | ℃ | 220 |

| working Temp. | ASTM D648 | ℃ | 70 |

| Permanent Temp. | – | ℃ | 85 |

| Short-period Temp. | – | ℃ | 160 |

| Pyroconductivity | DIN 52612-1 | W/(K-M) | 0.23 |

| dilatation coefficient | ASTM D696 | 10-5-1/K | 8 |

| electrical property | |||

| dielectric strength | ASTM D150 | KV-mm | 25 |

| dielectric loss coefficient | ASTM D150 | – | 0.032 |

| Volume resistance | ASTM D257 | Ω.cm | 1014 |

| surface resistance | ASTM D257 | Ω | 1016 |

| dielectric constant | ASTM D149 | – | 4.2 |

| Chemical properties | |||

| Water absorption | 23℃ 60%RH | % | 1.28 |

| Acid resistance | 23℃ 60%RH | – | |

| Alkali resistance | + | ||

| Resistance to acid and alkali water | + | ||

| Chloric acid alkali resistance | 0 | ||

| Resistant to aromatic compounds | + | ||

| The ketone resistance | 23℃ 60%RH | + | |

| Water resistance | 23℃ 60%RH | + | |

| Others properties | |||

| combustibility | UL 94 | HB | |

| paste | – | + | |

| Non-toxic harmless | EEC 90/128 FDA | + | |

| friction coefficient | DIN 53375 | 0.36 | |

| uvioresistant | – | – | |