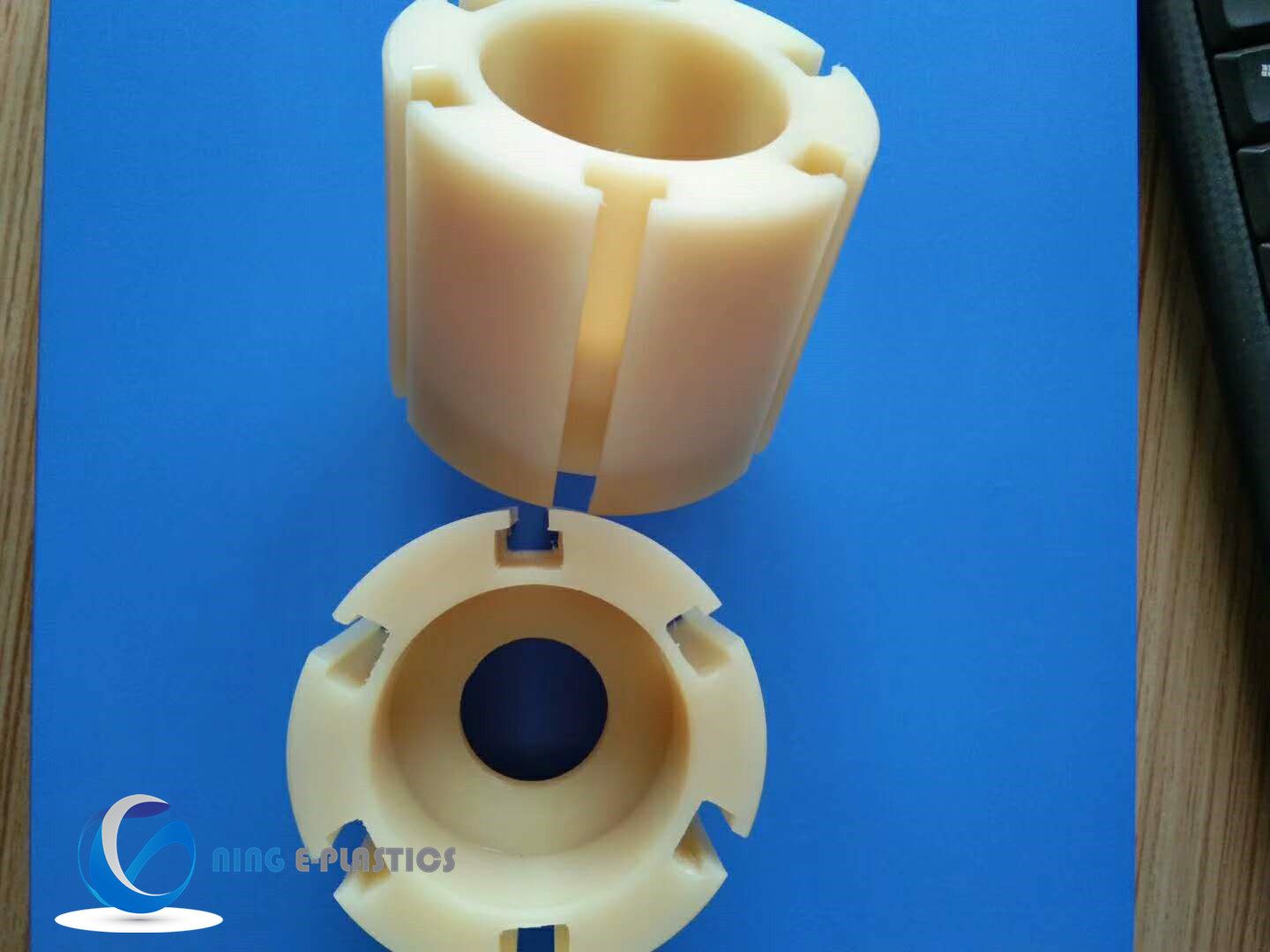

Versatile and Customizable O Rings

Discover the endless possibilities with our Custom Size Material Exercise Plastic PTFE Rubber or Seal O Rings. These O Rings are engineered to perfection, offering exceptional versatility and flexibility. With a wide range of materials to choose from, including ABS, PMMA, PC, PP, PEEK, PU, Nylon, POM, PE, UPE, and PTFE, you can easily find the perfect fit for your specific application. Whether you need a small diameter for precise sealing or a larger size for heavy-duty operations, our O Rings can be customized according to your requirements. Embrace the freedom of choice and experience the unmatched performance of our custom-made O Rings.

Unyielding Performance and Reliability

Experience the resilience and dependability of our Custom Size Material Exercise Plastic PTFE Rubber or Seal O Rings. These O Rings are designed to endure extreme conditions, boasting high and low-temperature resistance from -180°C to +260°C. Their exceptional corrosion resistance against strong acids, alkalis, and aqua regia ensures long-lasting functionality in demanding environments. With excellent insulation properties and non-toxic characteristics, these O Rings are ideal for various applications, including gaskets, valve packings, diaphragms, mechanical seals, linings of pipes, valves, pumps, and vessels. Trust in their superior properties to enhance the performance and efficiency of your systems.

Your One-Stop Procurement Solution

Embrace convenience and efficiency with our Custom Size Material Exercise Plastic PTFE Rubber or Seal O Rings. At Ning E-plastics, we pride ourselves on being your one-stop procurement solution for top-quality plastic sheets, tubes, rods, and custom O Rings. Our products come with ISO9001 and SGS certifications, ensuring exceptional quality and reliability. With a wide selection of shapes, colors, and materials, you can easily find all the components you need in one place. Benefit from our 24/7 customer service, shipping status notifications, and regular updates on new styles and best-selling products. Simplify your procurement process with us today!

| NAME | CUSTOM SIZE MATERIAL EXERCISE PLASTIC PTFE RUBBER OR SEAL O RINGS |

| Material | ABS,PMMA,PC,PP,PEEK,PU,Nylon,POM,PE,UPE,PTFE,etc. |

| Color | White,black,green,nature,blue,yellow,etc |

| Diameter | 5-1000mm,or customized |

| Tolerance | ±0.05 |

| Shape | As per your drawing Or the sample |

| Certification | ISO9001,SGS,Test Report,RoSH |

| Free Sample | Available |

| Shape | Sheet, rod, tube, gear, pulley, guide rail, and Plastic parts so on |

| Advantage | One stop procurement |

| Other | 24 hours instant and comfortable customer service. |

| Shipping status notification during delivery. | |

| Regular notification of new styles & hot selling styles. |

PTFE has the highest melting point and is capable of continued service at -180-260 C. PTFE is a melt processible resin capable of continued service at 204 C. PTFE products such as teflon gaskets are used as gasket and packing materials in chemical processing equipment; as electrical insulation for maximum reliabillity; and in bearings, seals, piston rings and other mechanical applications, especially those require anti-stick characteristics. PTFE has excellent thermal and electrical insulation properties. it has a low coefficient of friction.

Characteristics

High and low temperature resistance(-180ºC~+260 ºC)

Corrosion resistance(strong acid, strong alkali and aqua regia etc)

Weather resistance

High insulation

High lubrication

Non adhesion

Non toxic etc

Application

Widely used in Gasket,Valve packing’s,Diaphragms and mechanical seals .

linings of pipes ,valves ,Pumps and vessels .Chemical,Machinery fields .Electrical insulation parts .

| PROPERTIES | STANDARD | UNIT | RESULT |

| mechanical property | |||

| Density | g/cm3 | 2.10-2.30 | |

| Tensile strength | Mpa | 15 | |

| ultimate elongation | % | 150 | |

| Tensile strength | D638 | PSI | 1500-3500 |

| Produce Max.Temp | ºC | 385 | |

| hardness | D1700 | D | 50-60 |

| Impact strength | D256 | Ft./Lb./In. | 3 |

| Melting poing | ºC | 327 | |

| working Temp. | ASTM D648 | ºC | -180 ~260 |

| Elongation | D638 | % | 250-350 |

| Deformation % 73 0F ,1500 psi 24 hours | D621 | N/A | 4-8 |

| Deformation % 1000F,1500psi,24hours | D621 | N/A | 10-18 |

| Deformation % 2000F,1500psi 24 hours | D621 | N/A | 20-52 |

| lzod | 6 | ||

| Water absorption | D570 | % | 0.001 |

| Coefficient of Friction | N/A | 0.04 | |

| Dielectric constant | D150 | Ω | 1016 |

| Dielectric strength | D257 | Volts | 1000 |

| Coeffcient of thermal expansion 73 0F | D696 | In./In./Ft. | 5.5*10.3 |

| Coefficient of thermal conductivity | *5 | Btu/hr/ftz | 1.7 |

| PV at 900 ft./min | N/A | 2500 | |

| Colour | *6 | N/A | white |

| PTFE was widely used as resistant high & low temperature material,Corrosion-resistant materials,Insulation materials in the atomic energy,defense,aerospace,electronics,electrical,chemical industry,Machinery,instruments,meters,construction,textile,metal,surface treatment,pharmaceutical,medical.food and metallurgical smelting,and become irreplaceable products. | |||

1,152

1,152 Reviews

Reviews

MOQ:

MOQ:  Port:

Port:  Packaging:

Packaging:  Lead Time:

Lead Time:  Size:

Size:  Color:

Color: